Tel: +86 15051225801

Email: [email protected]

Tel: +86 15051225801

Email: [email protected]

Pressure grouting, a time-tested technique in civil engineering, has gained role in waterproofing. This Yuru epoxy grout for concrete, method of injecting a specialized grout material into soil under pressure, serves as a barrier against water ingress, that ensures the building structures is strong and can last long. This article will give a clear understanding about the products benefit, innovations or development, usage, safety and application.

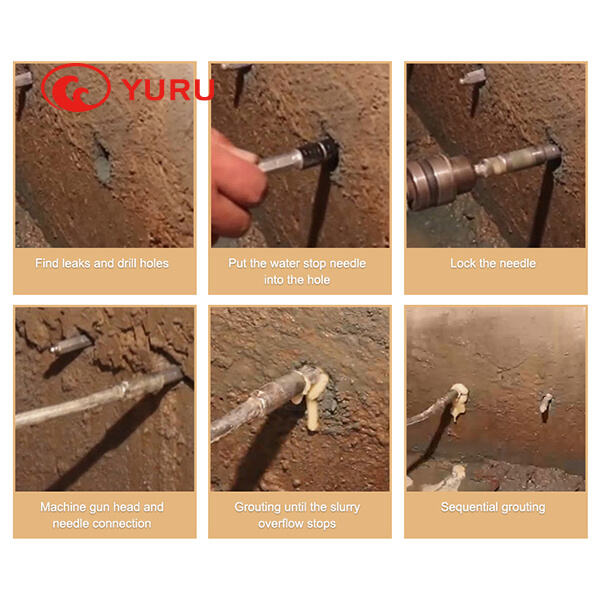

At its core, pressure grouting is all about the principles of fluid dynamics and soil mechanics. The Yuru epoxy injection grout in concrete, process is very simple, it begins by identifying weak points or pathways through which water infiltrates. Then, the mixture of cement or resin-based grout is prepared, and will be based on soil conditions and waterproofing requirements. Next is the Injection at high pressures, the grout displaces water, fills voids, and consolidates loose soils, effectively sealing them against further seepage. The balance between the injection pressure and viscosity of grout ensures maximum coverage without damaging.

Basements below ground level, are truly prone to water infiltration. So, the Yuru pu grouting waterproofing, Pressure grouting makes as a powerful defense mechanism, and be a shield against hydrostatic pressure. By addressing cracks, joints, and porous substrates, it not only prevents water from entering but also stabilizes the soil, and reduce the risk of foundation in any establishment. This product is really effective because it minimizes the risk in terms of constructing an establishment.

In this world of sustainability, this product is also environmentally-friendly that makes no harm to environment. It Yuru high pressure grout injection, doesn't require any special approaches just like the traditional one. Also, by enhancing the durability of structures, it reduces the overall carbon footprint associated with repairs and renovations. It is also cost-effective that don't need any special amounts just to ensure its effectiveness. It is perfect in making or practicing sustainable construction.

Beyond waterproofing, it significantly contributes to the overall stability and resilience of buildings to make it stronger. By compacting loose soils and reinforcing foundation footings, it can help minimizing the risk in the soil that makes the Foundation strong. It Yuru pu foam injection grouting, can also help to minimize the impact of any hazard like earthquakes and heavy rain fall. It can be the guardian in strengthening the buildings.

Our primary client are municipalities, constructions engineering companies and building material dealers. Exports to more than 70 countries and provide services to 10000 clients from around the world.

We develop Production of waterproof and injection grout materials. Our main product currently comprise all types of waterproof coatings membranes that are waterproof, injection grouting materials, grouting equipment, and polyurethane sealants.

Yuru is a company making a center that spans 16000 square meters s as well asR and D center which covers 10000 square meters. Yuru has five product series including over 40 models that are able meet needs of customers in all terms. Yuru has been rewarded more than 20 patents and collaborates with 10 doctors from two renowned universities.

The institutions is accredited through the lS09001, CE, EPR, SGS and various other certifications. It also has over 20 patents, including our waterproof product, which are protected through independent intellectual property rights. It was a recognized "high-tech enterprise in Jiangsu Province." of Jiangsu Province".

Copyright © Nantong Yuru Engineering Materials Co., Ltd. All Rights Reserved