Tel: +86 15051225801

Email: [email protected]

Tel: +86 15051225801

Email: [email protected]

Quick Detail:

1. Different names of products:

Acrylic Grout

2. Main uses:

Mainly used for anti-seepage curtain grouting of building structures that permanently bear water

pressure, such as dams, reservoirs, etc.; to control water penetration and solidify loose soil

waterproofing; used for anti-seepage and leakage plugging in underground building basements,

kitchens, toilets and bathrooms, etc. .

| Place of Origin: | Nantong, Jiangsu, China |

| Brand Name: | Yuru |

| Model Number: | YR-A204 |

| Certification: | CE |

| Minimum Order Quantity: | 100 kilograms |

| Price: | / |

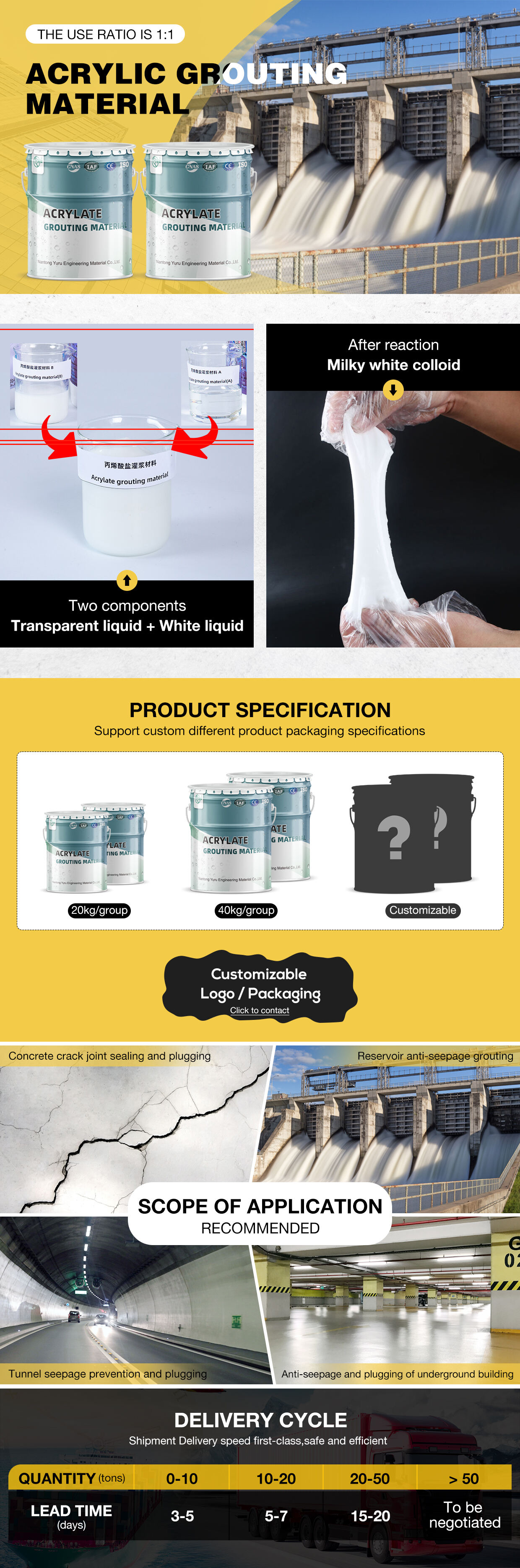

| Packaging Details: | 20kg/group |

| Packaging specifications can be customized | |

| Delivery Time: | 7-15days |

| Payment Terms: | T/T, L/C,paypal, western union |

| Supply Ability: | 1000 tons per month |

Description:

Acrylic grouting material is a kind of non-toxic and environmentally friendly grouting material with acrylic polymer as the main agent. Slurry viscosity is low, can be injected into the base of the micro cracks, solidification after the formation of a high flexibility, water can expand, impermeable elastic gel.

Advantages:

◇Low viscosity, high permeability environmental grouting material, suitable for any dense complex structure.

◇The low shrinkage formula with high viscosity, strength and toughness can effectively reduce the repeated seepage of foundation settlement or structure expansion.

Applications:

◇Anti-seepage grouting for DAMS, reservoirs, etc.

◇Seepage prevention and sealing of tunnel bushing.

◇Underground building, basement, kitchen, bathroom and other seepage plug leakage.

◇Seal cracks in concrete and rock structures against seepage and leakage.

Specifications:

| Item | Project | Test results |

| 1 | Viscosity /Mpa. S | 8 |

| 2 | Gel time /s | 20 |

| 3 | Permeability /cm/s | 0.9*10-6 |

| 4 | PH | 8.0 |

| 5 | Compressive strength of sand body/kPa | 255 |

| 6 | Resistance to extrusion damage ratio | 335 |

| 7 | Water expansion rate/% | 35 |

Competitive Advantage:

1. It can be quickly cured in only 30s-2min, and the curing time can be adjusted;

2. The gel has high elasticity and an elongation rate of up to 200%, which effectively solves the problem of structural expansion and contraction;

3. Good pourability and good impermeability;

4. The bonding strength is also greater than the strength of the gel itself, and the bonding surface remains intact;

5. Has good chemical resistance;

6. Non-toxic, environmentally friendly and harmless to the human body.

Key points of construction:

◇Check the leaking part, clean the leaking part, confirm the crack type, drill hole, install the grouting nozzle on the effective grouting hole.

◇According to the proportion of materials prepared into A, B two components, the use of double liquid high-pressure grouting machine, according to the volume of 1:1 construction, grouting machine should be kept dry before construction, no dirt.

◇Starting from the first grouting nozzle from low to high, grout is injected and the pressure is gradually increased. When the grout appears in the adjacent grouting hole, it is moved to the next adjacent grout hole and the grout is continued. After all grout is finished, it is returned to the first grouting nozzle and grout again.

◇72 hours after the completion of grouting, check the leakage site for water seepage. If there is no water seepage, remove the grouting nozzle and seal and smooth the base surface with epoxy mortar or quick-dry cement.

◇After construction, immediately use cleaning agent to clean the desired equipment and tools in contact with slurry. Waste should be centralized treatment, not discarded at will.

Storage and transportation:

◇Stored in a dry, cool place.

◇Shelf life: 6 months from the date of production.

Copyright © Nantong Yuru Engineering Materials Co., Ltd. All Rights Reserved