Tel: +86 15051225801

Email: [email protected]

Tel: +86 15051225801

Email: [email protected]

Quick Detail:

1. Different names of products:

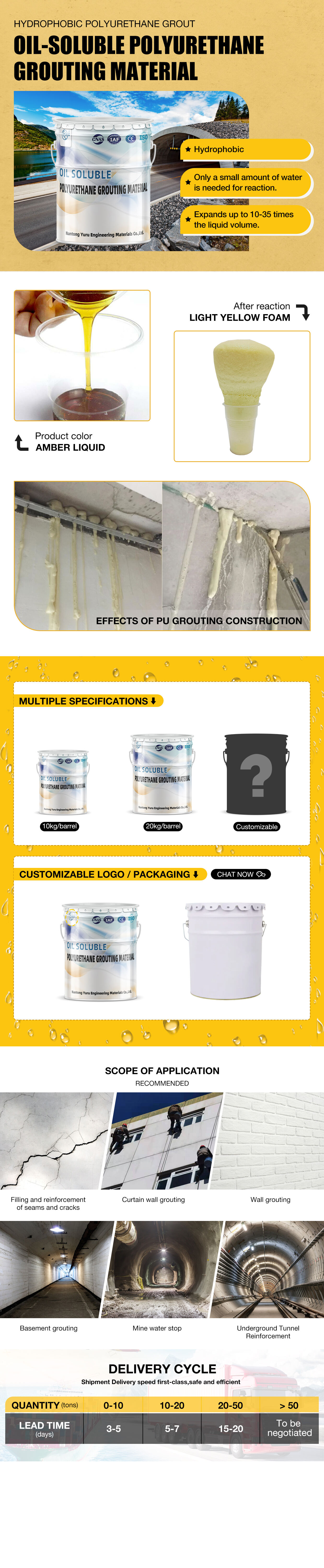

Hydrophobic Polyurethane Grout/PU Injection Grout/oil-soluble polyurethane grouting material/Polyurethane chemical grouts /PU foam injection grout

2. Main uses:

It is mainly used to fill micro cracks in concrete, brick walls, stone and other buildings to achieve waterproofing and anti-seepage purposes; it can also be used to stop water leakage of iron oxide red, grout gaps in building structures, and reinforce Reinforcement works.

| Place of Origin: | Nantong, Jiangsu, China |

| Brand Name: | Yuru |

| Model Number: | YR-O202 |

| Certification: | CE |

| Minimum Order Quantity: | 100 kilograms |

| Price: | / |

| Packaging Details: | 10kg/barrel |

| Packaging specifications can be customized | |

| Delivery Time: | 7-15days |

| Payment Terms: | T/T, L/C,paypal, western union |

| Supply Ability: | 1000 tons per month |

Description:

Oil soluble polyurethane grouting materials by composite polyether polyol and polyisocyanate reaction generated by isocyanate terminated a chemical grouting material. The material meets the water after a chemical reaction, the volume expansion and generate a insoluble in water foaming body, can not only waterproof plugging, more certain reinforcement reinforcement effect, are widely used in the subway tunnel, water conservancy and hydropower, underground garage, and sewers waterproof plugging reinforcement engineering.

Advantages:

◇Has good hydrophobic performance, high chemical stability.

◇With a larger infiltration radius and solidification volume ratio, the water in the case of rapid chemical reaction, and will produce a large expansion pressure, to promote the formation of the slurry to the cracks in the formation of a strong consolidation of the consolidation.

◇Acid, alkali and organic solvents, good chemical resistance.

◇Coating smooth, wear-resistant, not long mildew.

◇Excellent bonding performance with concrete base and other building materials.

◇The viscosity and cure rate of grouting glue can be adjusted according to the engineering requirements.

Applications:

◇The pool, water tower, basement, grouting shelter and other buildings.

◇Underground tunnel, building foundation reinforcement and ground dust treatment.

◇Deformation joints, construction joints, cracks in the construction of the building, plugging and reinforcement.

◇Port, wharf, bridge pier, dam, dam, hydropower station, curtain grouting, plugging and reinforcement.

◇The geological drilling wall plugging, water gushing water and mine selective oil exploration in the block.

Specifications:

| Item | Project | Index |

| 1 | Appearance | Uniform liquid, no impurities, no stratification |

| 2 | Density,g/cm³ | 1.165 |

| 3 | Viscosity,Mpa.s | 3.3*10² |

| 4 | Reaction time, S | 20 |

| 5 | Coagulation time, S | 80 |

| 6 | Nonvolatile content,% | 85 |

| 7 | Foaming rate,% | 2200 |

| 8 | Compressive Strength,Mpa | 40 |

Competitive Advantage:

1. The expansion rate is large and does not shrink. Normally, the slurry reacts with water to form a foam 10-30 times, which can further fill the gaps and play a waterproof and leak-proofing role.

2. It forms an impermeable chemical substance after reacting with water. It reacts in a few seconds and completes solidification within 1-3 minutes. It will not cause corrosion or damage to the concrete structure and steel bars.

3. The viscosity and curing speed of the grouting material can be adjusted according to project needs.

4. It is easy and fast to use, especially in emergency rescue. It can play an immediate role.

Key points of construction:

◇Cleaning: carefully check the Water Leakage site, identify the leak, remove the dirt around the crack.

◇Punch: in leakage cracks on both sides of the cross hole spacing is 200-500mm, the leak can be intense.

◇Burying water stop needle: holes where buried good fit the length of the needles in the, and then one by one tightly needle, let parts of rubber inflation and deflation in wall body, hands touch not shaking so far.

◇Grouting: high pressure grouting can be taken, from bottom to top one by one to control the pressure in the needle, to see the adjacent cracks at the bottom of the pure pulp.

◇Knock out needle: after grouting, use a small hammer to gently knock out the needle outside the concrete.

Storage and transportation:

◇Stored in a dry, cool place.

◇The collision, transport may not be straight sun, rain, prevent fireworks.

◇Shelf life under original package: 6 months.

Copyright © Nantong Yuru Engineering Materials Co., Ltd. All Rights Reserved