Tel: +86 15051225801

Email: [email protected]

Tel: +86 15051225801

Email: [email protected]

Quick Detail:

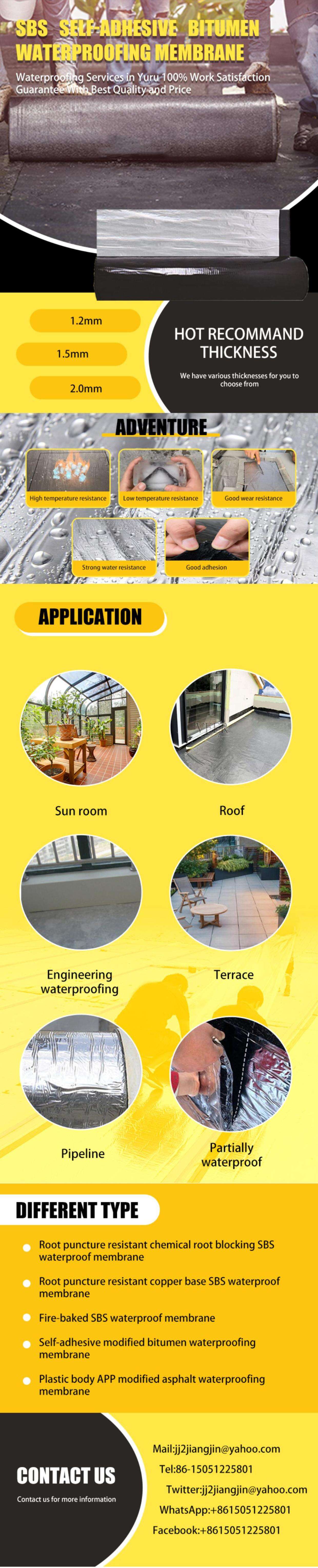

1. Different names of products:

sbs modified bitumen waterproof membrane

sbs waterproof membrane

bituminous waterproofing membranes

sbs modified bitumen waterproof membrane for roof

sbs bitumen waterproof membrane

2. Main uses:

It is suitable for waterproofing and anti-seepage of roofs, basements, bathrooms, roads, bridges, tunnels, grain depots, parking lots, swimming pools, artificial lakes, anti-seepage ditches, cabins, roof gardens, urban greening and other projects in industrial and civil buildings. and moisture-proofing and asphalt roofing repair projects. Elastomer (SBS) modified asphalt waterproofing material is especially suitable for building waterproofing in cold areas and areas with frequent structural deformation.

| Place of Origin: | Nantong, Jiangsu, China |

| Brand Name: | Yuru |

| Model Number: | YR-SBS |

| Certification: | CE |

| Minimum Order Quantity: | 100 Square Meter |

| Price: | / |

| Packaging Details: | Roll |

| customizable | |

| Delivery Time: | 7-15days |

| Payment Terms: | T/T, L/C,paypal, western union |

| Supply Ability: | 30,000 rolls per month |

Description:

Elastomer (SBS) modified asphalt waterproofing membrane is made of SBS (styrene-butadiene-ethylene) thermoplastic elastomer modified asphalt as dipping material, and is made of high-quality polyester felt, glass fiber felt and glass fiber reinforced polyester felt. It is an elastomer-modified asphalt waterproof membrane made of fine sand, mineral granules, PE film, aluminum film, etc. as covering materials, and is stirred and ground by special machinery.

Features:

·Strong water impermeability.

·High tensile strength, large elongation, and strong adaptability to shrinkage, deformation and cracking of the base layer.

·Good low temperature performance, can still maintain efficacy at -50°C, suitable for both hot and cold areas, especially cold areas

·Puncture-resistant, puncture-resistant, tear-resistant, corrosion-resistant, mildew-resistant and weather-resistant.

·Easy to construct, the hot melt method can be operated in all seasons, and the joints are reliable.

Applications:

1. Polyester felt-based elastomer-modified asphalt waterproofing membrane is suitable for roofing and underground waterproofing projects in industrial and civil buildings.

2. Glass fiber reinforced polyester felt base roll is suitable for mechanically fixed single-layer waterproofing, but it needs to pass the wind load test.

3. Glass fiber felt matrix membrane is suitable for general roofing and underground waterproofing projects with stable structure;

4. For exposed areas, use waterproof membranes with opaque mineral granules as the isolation material on the upper surface.

5. For underground engineering waterproofing, waterproofing membranes whose surface isolation material is fine sand should be used.

Specifications:

| No. | Project | I | II | ||||

| PY | G | PY | G | PYG | |||

| 1 | Soluble content / (g/m²)≥ | 3cm | 2100 | * | |||

| 4cm | 2900 | * | |||||

| 5cm | 3500 | ||||||

| Experimental phenomenon | * | The tire base is non-flammable | * | The tire base is non-flammable | * | ||

| 2 | Heat resistance | ℃ | 90 | 105 | |||

| ≤mm | 2 | ||||||

| Experimental phenomenon | No flowing or dripping | ||||||

| 3 | Low temperature flexibility/℃ | -20 | -25 | ||||

| No cracks | |||||||

| 4 | Water impermeability 30min | 0.3Mpa | 0.2Mpa | 0.3Mpa | |||

| 5 | Pull | Maximum peak pulling force/(N/50mm)≥ | 500 | 350 | 800 | 500 | 900 |

| Second peak pulling force/(N/50mm)≥ | * | * | * | * | 800 | ||

| Experimental phenomenon | During the stretching process, there was no cracking or separation of the asphalt coating layer from the tire base in the middle of the specimen. | ||||||

| 6 | Elongation | Maximum peak elongation/%≥ | 30 | * | 40 | * | * |

| Elongation at the second peak/%≥ | * | * | 15 | ||||

| 7 | Oil permeability | Number of sheets≤ | 2 | ||||

Competitive Advantage:

Excellent impermeability: SBS waterproof membrane has extremely strong water resistance and can effectively prevent underground water, ground water, rainwater, etc. from penetrating into the interior of the building.

Good chemical resistance: SBS waterproof membrane can resist the erosion of various chemical substances such as acids, alkalis, and salts, thereby extending its service life.

High elasticity and high toughness: SBS waterproof membrane has extremely high elasticity and toughness, and can effectively adapt to changes in various complex building structures, thereby ensuring the sealing performance of the building.

Convenient construction: SBS waterproof membrane is simple and convenient to install, does not require too much professional technology and equipment, and can greatly shorten the construction period.

01 Construction points:

[Grassroots requirements]

·The base layer must be smooth, clean, dry, and the moisture content should be less than 9%. Then use base oil to evenly brush the surface of the base layer, and wait until it is dry before construction; if cold bonding is used for construction, no painting is required.

·For joints, holes, trenches, walls, pipes, and corners with complex shapes, concentrated stress, and easy leakage, reinforcement layer construction must be carried out.

【Paving method】

·Hot melt method: Use a flame spray gun or other heating tool to heat the bottom surface of the membrane and the base layer evenly. When the asphalt on the surface begins to melt and becomes black and shiny, bake the membrane while paving it, and compact it with a pressure roller. At the same time, attention should be paid to adjusting the size and speed of the flame to keep the asphalt temperature between 200 and 250°C. After the construction is completed, the overlapping edges should be sealed with cold adhesive. Hot melt method construction shall not be carried out in gas stations, flour mills, chemical plants and other flammable and explosive places.

·Cold bonding method: Use a rubber scraper to evenly apply cold adhesives such as polymer modified asphalt adhesive or cold marse on the surface of the base layer, and control the thickness to be uniform. While laying the roll, use a rubber roller to push the roll to remove air. To compaction, when the ambient temperature is lower than 15°C, the hot melt method should be used to treat the overlapping parts and coil closing parts.

·When paving membranes on facades or large slopes, in order to prevent the membrane from sliding down and to facilitate the firm attachment of the membrane to the base layer, it is stipulated that the full-adhesive method should be used for paving. If necessary, metal strips should be used to fix the membrane and be sealed with sealing materials. Be strict and minimize overlap on short sides.

02Matters need attention:

·During storage and transportation, products of different types and specifications should be stored separately and should not be mixed; avoid sunlight and rain, and pay attention to ventilation;

·The storage temperature should not be higher than 50°C. It can only be stored vertically in a single layer and placed in no more than two layers during transportation;

·Prevent tilting or horizontal pressure during transportation, and cover with tarpaulin if necessary.

Copyright © Nantong Yuru Engineering Materials Co., Ltd. All Rights Reserved