Tel: +86 15051225801

Email: [email protected]

Tel: +86 15051225801

Email: [email protected]

Quick Detail:

1. Different names of products:

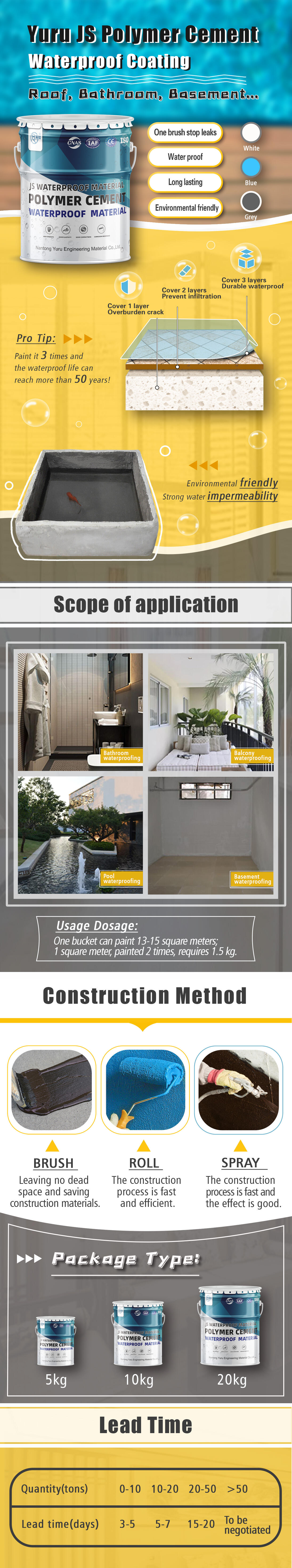

Polymer cement waterproof coating/JS waterproof coating/JS polymer waterproof coating

2. Main uses:

Widely used in waterproofing, seepage and moisture-proofing of exterior walls, bathrooms, kitchens, roofs, floors, garage floors, pools, roads and bridges, water conservancy projects, etc.

Description:

Polymer cement waterproof coating (JS waterproof coating) is made of polymer emulsion and various inorganic additives through scientific formula and processing of two-component waterborne waterproof coatings.

| Place of Origin: | Nantong, Jiangsu, China |

| Brand Name: | Yuru |

| Model Number: | YR-JS301 |

| Certification: | CE |

| Minimum Order Quantity: | 100 kilograms |

| Price: | / |

| Packaging Details: | 20kg |

| barrelPackaging specifications can be customized | |

| Delivery Time: | 7-15days |

| Payment Terms: | T/T, L/C,paypal, western union |

| Supply Ability: | 1000 tons per month |

Features:

◇The product is an environmentally friendly water-based waterproof coating, which is non-toxic, harmless, pollution-free and safe to use.

◇Type II and III products have excellent bonding strength, good water resistance, and good affinity with cement mortar, ceramic tiles and other materials.

◇Can be applied directly on wet (no clear water) or dry substrates of various materials.

◇The coating is tough, high-strength, water-resistant, and has excellent durability.

◇Can be constructed directly on facades, slopes and top surfaces without flowing, easy to construct and easy to operate.

◇Excellent weather resistance.

◇Type I products have excellent flexibility and good low temperature resistance.

◇It has strong adhesion and can be firmly bonded to various base materials such as base surface and cement mortar.

Applications:

Type I: Suitable for drier, non-long-term water immersion environments, and locations with vibration loads or large base displacements, such as roofs, etc.

Type II: Suitable for long-term water immersion environments, such as bathrooms and underground buildings.

Type III: Suitable for waterproofing and seepage-proofing in kitchens and bathrooms, pools, swimming pools, and overall waterproofing and moisture-proofing of indoor and outdoor walls.

Specifications:

| Item | Project | Index | ||

| I | II | III | ||

| 1 | Tensile strength/Mpa≥ | 1.2 | 1.8 | 1.8 |

| 2 | Elongation at break/%≥ | 200 | 80 | 30 |

| 3 | Low temperature flexibility(ɸ10mm) | -10℃,(No crack) | - | - |

| 4 | Water impermeability(0.3MPa,30min) | Impervious | Impervious | Impervious |

Competitive Advantage:

1. Long service life. After painting 3 times, the service life can reach more than 30 years.

2. Excellent waterproof performance: JS polymer waterproof coating forms a seamless waterproof layer, which can effectively prevent moisture penetration and provide long-lasting waterproof protection. The active ingredients in the slurry can penetrate into the pores and micro-cracks in the cement base surface to produce chemical reactions, penetrate into the cement base surface and crystallize to form a dense waterproof layer; it can cover hairline cracks (less than 0.4 mm), Resist slight shock and cracking effect.

3. Good elasticity and flexibility: JS polymer has excellent elasticity and flexibility, able to adapt to temperature changes and small movements of the substrate, reducing the risk of coating cracking.

4. Excellent weather resistance: JS polymer waterproof coating is resistant to the effects of ultraviolet radiation, chemicals and climate change, and can maintain stable performance under various environmental conditions.

5. Environmentally friendly and non-toxic: JS polymer waterproof coating does not contain harmful substances, is non-toxic and harmless to the human body and the environment, and meets environmental protection standards.

01 Construction points:

◇Preparation of the base layer: Make the surface of the base layer smooth, solid, free of sharp corners, floating dust and open water, and prepare waterproof nodes according to the design requirements. Clean the oil stains and smooth out the damaged areas.

◇Ingredients: Proportion according to the proportion of liquid, powder and water marked on the product packaging. The amount of water added can be adjusted appropriately to adjust the paint viscosity to meet the construction requirements of different parts of the facade and plane.

◇Additional waterproof layer in details: Fill the remaining grooves with sealing material according to the design requirements. Details such as yin and yang corners, pipe roots, etc. should be processed multiple times. Underground projects should be sandwiched with a layer of carcass reinforcement material.

02Matters need attention:

Restricted to use in rainy, snowy, sandy, and low-temperature weather.

Storage and transportation:

During transportation, prevent rain, exposure to the sun, and freezing, avoid squeezing and collision, and keep the packaging intact. The product should be stored in a dry, ventilated, and cool place, and the storage temperature of the liquid components should not be lower than 5°C.

Reference dosage:

For each millimeter of coating film thickness, the amount of paint used is approximately: 2.2kg/㎡-2.5kg/㎡.

Copyright © Nantong Yuru Engineering Materials Co., Ltd. All Rights Reserved