Tel: +86 15051225801

Email: [email protected]

Tel: +86 15051225801

Email: [email protected]

Quick Detail:

1. Different names of products:

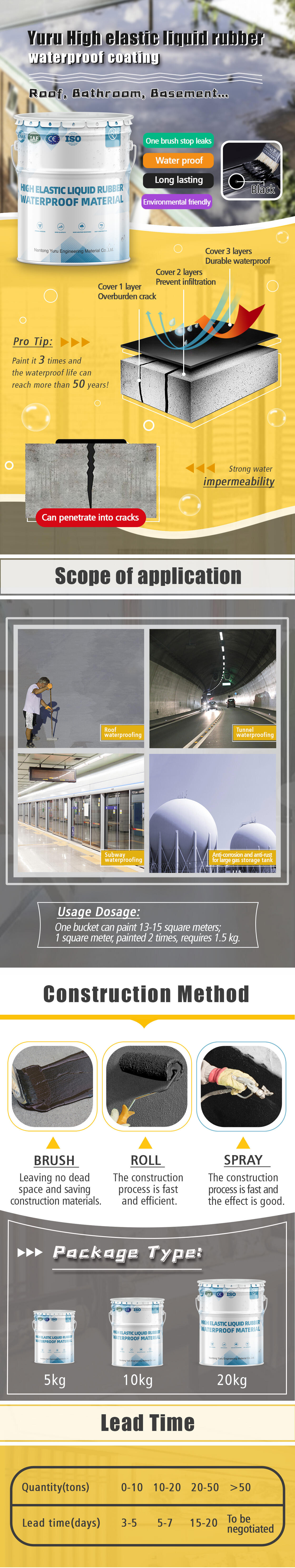

High elastic rubber waterproof coating/High elastic rubber waterproof paint/liquid rubber waterproof coating

2. Main uses:

1. Suitable for roofing, underground waterproofing and industrial anti-corrosion protection projects, etc.

2. Waterproof protection and anti-seepage projects for various above-ground and underground concrete structures and other foundations

3. Waterproofing and protection projects for subways, tunnels, road bridges, and large pools

4. Industrial buildings and chemical equipment: anti-corrosion and anti-rust for large gas storage tanks, etc.

| Place of Origin: | Nantong, Jiangsu, China |

| Brand Name: | Yuru |

| Model Number: | YR-HE304 |

| Certification: | CE |

| Minimum Order Quantity: | 100 kilograms |

| Price: | / |

| Packaging Details: | 20kg/barrel |

| Packaging specifications can be customized | |

| Delivery Time: | 7-15days |

| Payment Terms: | T/T, L/C,paypal, western union |

| Supply Ability: | 1000 tons per month |

Description:

High elastic liquid rubber waterproof coating, also known as "Four Not Afraid" high elastic skin type rubber waterproof coating, is called "Four Not Afraid" because it is not afraid of water leakage, aging, cracking and deformation, and puncture. When a knife is inserted into the paint and then pulled out, the knife edge heals quickly without leaking, and can be stretched by 20 cm by 1 cm. The deformation capacity is 20 times that of the original, and the bonding force is four times that of cement. The paint does not flow at 80 degrees Celsius and is flexible at -30 degrees Celsius. Its waterproofing ability far exceeds that of JS and K11 waterproof coatings, and is better than leak plugging and cement-based penetration crystallization.

Features:

◇High elasticity

The elastic coating film has good elongation and high recovery rate, so it can effectively solve the problems of leakage, corrosion and other problems caused by stress deformation, expansion cracking, puncture or weak connection of various structures.

◇Weather resistance

The strong polymer liquid rubber is not affected by the temperature after film formation. It will not be brittle and broken under cold climate conditions of -35°C, and will not flow under high temperature conditions of 140°C.

◇Good adhesion

It can be attached to the surface of concrete, light bricks, PVC boards, galvanized boards, mineral wool boards, SBS double-sided membranes, ceramic tiles, glass, aluminum boards, extruded boards, geotextiles, steel, wood and other materials without layering. It does not peel or fall off, and has a good protective effect on the base layer.

◇Creep crack resistance

Polymer liquid rubber reduces the impact of base stress on the waterproof layer through its own flexible creep. When the deformation coating of the base layer is stretched, the creep of the bonding layer can release the stress and prevent the waterproof layer from cracking due to the deformation of the base layer due to its "zero extension". At the same time, it will not accelerate aging due to long-term exposure to high stress.

◇Self-healing property

After the polymer liquid rubber waterproof layer and the base surface are cracked, damaged, or pierced by foreign objects, the adhesive film layer will crawl toward the crack or hole to reduce the internal stress of the adhesive film layer at the hole and block it. Defects prevent moisture from passing through, prevent "water channeling" from occurring, and improve the reliability of waterproofing.

◇Anti-water channeling

Preventing water channeling needs to be solved by full viscosity. Due to the uneven microstructure of the construction base surface, the adhesive material for ordinary waterproofing membrane construction can only stick to the protruding parts of the base surface. Although the bonding appears to be relatively strong on the surface, in fact, large and small pits on the surface are It is a channel for flowing water. The polymer liquid rubber waterproof layer constructed by spraying can fully adhere to the base surface.

◇Adhesion to wet base surfaces

Water-emulsion polymer liquid rubber can be constructed on wet base surfaces without open water. The polymeric polymer chains after spray demulsification can extend into the microporous base surface like "hooks" and firmly "grasp" the base surface; this electrochemical reaction of fast setting and slow cracking makes the water-emulsified polymer The liquid rubber infiltrates into the surface of the base layer, providing sufficient adhesion between the coating and the base layer.

◇Quick and easy construction

Special spraying machinery is used for construction, and it takes shape instantly after spraying. The designed thickness can be reached in one spray, saving labor, greatly shortening the construction period, and reducing construction costs. A spraying equipment with 3-5 people can provide two sets of nozzles for spraying at the same time, and the daily construction capacity can reach 1200㎡-1800㎡.

◇Functional diversity

Forming a complete coating on the base surface, in addition to achieving excellent waterproof performance, it can also achieve multiple functions such as anti-corrosion, protection, shock absorption, anti-drying, shielding, insulation, flame retardancy, etc. It can be used in roofs, basements, subways, Tunnels, bridges, water conservancy and other waterproofing and industrial anti-corrosion and protection engineering fields.

◇Environmental protection and energy saving

From the raw material production, spraying construction and use process, it is non-toxic, tasteless, no waste, no waste gas emissions, and no pollution. It is a new generation of energy-saving, ecological and environmentally friendly materials; during the entire construction process, no heating is required, construction is at room temperature, and there is no open flame. , ensuring the safety and reliability of construction; adopting the new development trend in the waterproof industry - single-layer waterproof materials, which not only reduces the amount of building materials, saves resources, but also reduces the construction waste generated during future demolition, truly achieving material and energy saving.

◇Flexibility in coating methods

Coating methods such as spraying, brushing and scraping can be used, which is flexible and simple. It can meet the special requirements for waterproofing in various environments such as drainage outlets, yin and yang angles, cracked parts, etc.

◇Good wrapping properties

The coating can well cover the substrate and achieve a seamless connection between the coating and the substrate, thereby achieving the non-channeling and non-peeling properties that are difficult to achieve with coiled materials. It is easier and more reliable for base construction of special-shaped structures or complex shapes.

Applications:

◇Suitable for roofing, underground waterproofing and industrial anti-corrosion protection projects.

◇Waterproof protection and anti-seepage projects for various above-ground and underground concrete structures and other foundations.

◇Waterproofing and protection projects for subways, tunnels, road bridges, and large pools.

◇Industrial buildings and chemical equipment: anti-corrosion and anti-rust for large gas storage tanks.

Specifications:

| Item | Project | Performance index | |

| L | H | ||

| 1 | Surface drying time/h≤ | 8 | |

| 2 | Fully drying time/h≤ | 24 | |

| 3 | Impermeability | 0.10MPa, 30min, No water seepage | |

| 4 | Low temperature temperature a/℃(standard conditions) | -15 | 0 |

| 5 | Elongation at break/%≥ | 600 | |

Competitive Advantage:

1. Long service life. After painting 3 times, the service life can reach more than 30 years.

2. Ultra-high elasticity, effectively solving leakage, corrosion and other problems caused by stress deformation, expansion cracking, puncture or weak connections in various structures.

3. Environmentally friendly, non-toxic and harmless.

4. It can resist small cracks on walls and floors, and the waterproof effect is maintained for a long time.

5. Good waterproof performance and good water-isolating performance, which can prevent rainwater and sewage from penetrating into the interior of the building, effectively preventing water leakage.

01 Construction points:

◇Grassroots requirements:

√The cement mortar leveling layer should be solid and smooth, and should not be loose, sandy or peeling.

√Pipes, embedded parts, equipment foundations, reserved holes, etc. that penetrate the waterproof layer should be buried and installed firmly before the construction of the waterproof layer.

√The corners protruding from the base layer should be formed into arcs, and the radius of the arc should be 50mm.

√The base layer should be clean and free of floating dust, oil stains and debris.

√The base layer can be wet, but there must be no open water.

√The drainage slope of the base layer should meet the design requirements.

◇Construction process:

√Process flow: base layer acceptance-cleaning the base layer-detail protection-additional layer of detailed structure-large area spraying = quality inspection-quality acceptance (water spray and water storage test)-protective layer construction.

√The additional layer of detailed structure is constructed by brushing method, which is applied in separate layers. The carcass reinforcement material should be sandwiched in the middle of the coating, and it should be laid firmly and firmly without hollowing or warping.

√Spraying large-area high-elastic rubber waterproof coatings should comply with the following regulations:

A. Large-area spraying should be carried out after the base layer meets the construction requirements.

B. The high-elastic rubber waterproof coating should be sprayed evenly and in consistent thickness. The distance between the nozzle and the spraying surface should be 600-800mm. A 2mm thick coating can be sprayed 4-5 times in a row in a criss-cross pattern.

C. When spraying the high-elastic rubber waterproof layer with carcass reinforcement materials, the following requirements should be met: The carcass reinforcement materials should be laid after the bottom layer of high-elastic rubber waterproof coating film is cured; the thickness of the bottom layer of high-elastic rubber waterproof coating film should not be less than 0.5mm; the laying of carcass reinforcement materials should be straight, smooth and without wrinkles. Apply high-elastic rubber waterproof coating to the overlap by rolling method; the overlap width of the long side of the carcass reinforcement material shall not be less than 50mm, and the overlap width of the short side shall not be less than 70mm. Apply a thick paste high-elastic rubber waterproof coating to the overlap joint. , adhere and seal firmly by rolling; when spraying high-elastic rubber waterproof coating on the carcass reinforcement material, there must be no defects such as hollows and openings, and its thickness should not be less than 1.0mm.

√After spraying high-elastic rubber waterproof coating on a large area, quality inspection should be carried out. Check the detailed structure, spraying quality, coating thickness, apparent quality, etc. If defects are found, they should be repaired in time. Spraying should be used for large-area repairs, and high-elastic rubber waterproof paint (Type III) should be used for detailed structures and small-area repairs.

02 Matters need attention:

◇Construction is divided into spraying method, brushing method and scraping method. The spraying method should be used for large-area construction. The brushing method should be used to strengthen details such as pipe roots, drains, parapets, etc. The scraping method should be used for repairing cracks and construction in areas that are not easy to spray.

◇The construction environment temperature of high elastic rubber waterproof coating is 5℃-35℃. Construction is not allowed on rainy days, snowy days, and winds above level 5.

Storage and transportation:

During transportation and storage, different types of products should be stacked separately and should not be mixed. Avoid sunlight and rain, pay attention to ventilation, and the storage temperature is (5-40)℃. Under normal transportation and storage conditions, the storage period is 12 months.

Reference dosage:

For each millimeter of coating film thickness, the amount of paint used is approximately: 2.2kg/㎡-2.5kg/㎡.

Copyright © Nantong Yuru Engineering Materials Co., Ltd. All Rights Reserved