Тел:+86 15051225801

Электронная почта:[email protected]

Тел:+86 15051225801

Электронная почта:[email protected]

Быстрая деталь:

1. Разные названия продуктов:

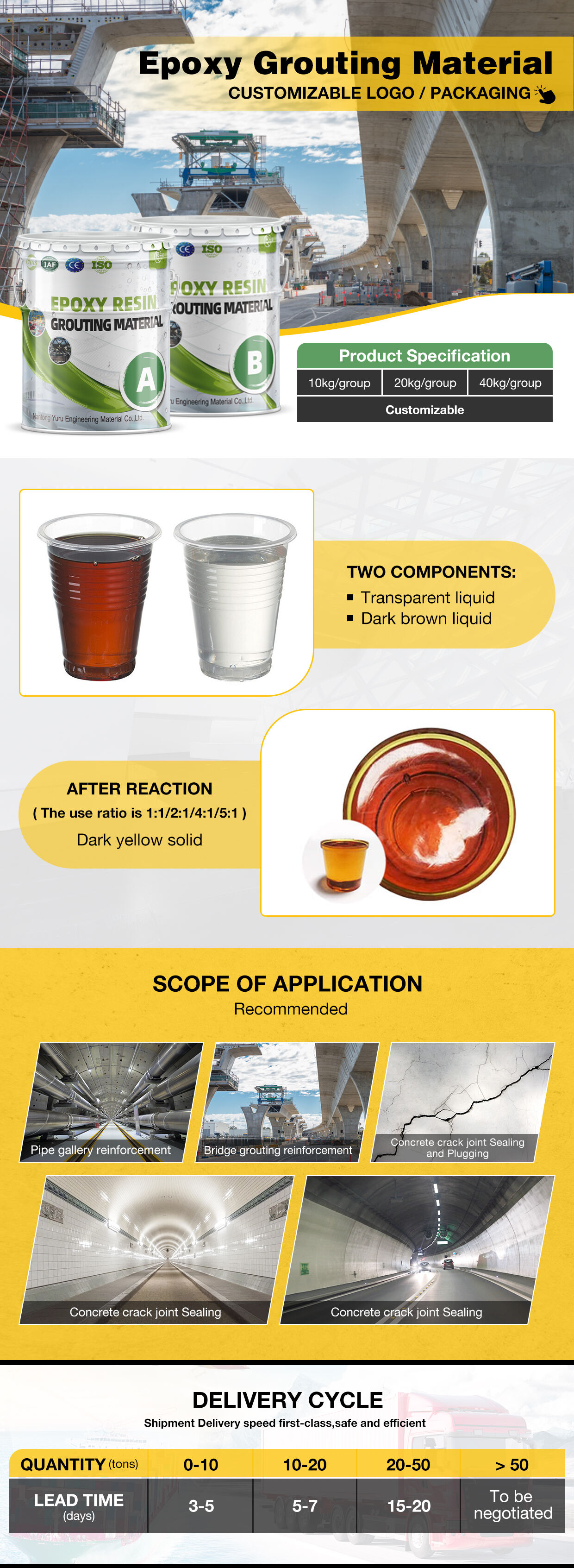

Эпоксидный инъекционный материал/Эпоксидная затирка/Эпоксидная смола для инъектирования

2. Основное применение:

Основное применение - армирование, усиление и предотвращение утечек в туннелях, метро и других подземных сооружениях, а также заполнение маленьких щелей в бетонных конструкциях и ремонт пустот в стенах из тонкого бетона.

- Что-то не так?

Пожалуйста, свяжитесь с нами, чтобы мы могли вам помочь!

| Место происхождения: | Наньтong, провинция Цзянсу, Китай |

| Название бренда: | Yuru |

| Номер модели: | YR-E203 |

| Сертификация: | СЕ |

| Минимальное количество заказа: | 100 килограммов |

| Цена: | / |

| Подробности упаковки: | 20кг/группа |

| Упаковочные спецификации могут быть настроены под ваши требования | |

| Время доставки: | 7-15 дней |

| Условия оплаты: | T/T, L/C, paypal, western union |

| Способность поставки: | 1000 тонн в месяц |

Описание:

Двухкомпонентный модифицированный эпоксидный материал для заполнения трещин, с высоким содержанием твердых веществ, хорошей проникающей способностью и отверждением при комнатной температуре. Подходит для ремонта эпоксидных конструкций. Используется для ремонта трещин, с низким выделением тепла при отверждении, прочной и гибкой структурой, низким усушным коэффициентом, отличным сцеплением и антираскалыванием различных конструкций.

Преимущества:

◇Высокая прочность, отличное адгезивное соединение, малое уменьшение объема, стабильные химические свойства.

◇Низкая вязкость, хорошая способность к пропитке, также обладает отличной способностью к пропитке мелких трещин.

◇Отношение компонентов может регулироваться в зависимости от температуры на строительной площадке, что обеспечивает гибкость строительства.

◇Этот продукт одновременно обладает функциями усиления, укрепления, заделки, гидроизоляции и противокоррозийной защиты.

Применение:

◇Усиление, укрепление и предотвращение протечек в туннелях, метро и других подземных сооружениях.

◇Усиление, укрепление и заделка утечек в балках, колоннах, сваях с пчелиными сотами, трещинами и другими дефектами.

◇Укрепление, гидроизоляция и предотвращение протечек дамб, портов, причалов, бассейнов и водонапорных башен.

◇Уплотнение стыков водопроводных и химических труб, остановка коррозии и т.д.

Спецификации:

| Товар | Проект | Индекс |

| 1 | Плотность суспензии/g/m³> | 1.0 |

| 2 | Начальная вязкость/mpa.s< | 500 |

| 3 | Время работы/min> | 30 |

| 4 | Сжимающая прочность/Mpa≥ | 40 |

| 5 | Предел прочности на растяжение/МПа≥ | 10 |

| 6 | Давление проникновения/Mpa≥ | 1.0 |

Конкурентное преимущество:

(1) Высокая ранняя прочность обеспечивает лучшие механические свойства, такие как сопротивление сжатию и сцепление, по сравнению с цементными материалами, а также обладает более высокой ранней прочностью.

(2) Отсутствие усадки гарантирует, что слой затирки после окончательного формирования полностью контактирует с опорной поверхностью, обеспечивая высокую точность при установке оборудования.

(3) Сопротивление ползучести: может использоваться длительное время без пластической деформации при суровых физических условиях от -40°C до +80°C, циклах замораживания-оттаивания, вибрации и давления.

(4) Высокая вязкость способна поглощать динамическую нагрузку, передаваемую движущимися механизмами, которая может вызвать разрушение цементного слоя заполнения.

(5) Коррозионная стойкость: может выдерживать длительное воздействие химических веществ, таких как кислоты, щелочи, соли и смазочные материалы.

Ключевые моменты строительства:

◇В соответствии с различными типами пропорций, равномерно смешайте компоненты A и B согласно стандартному соотношению и введите их в структурные трещины или зазоры через высокодавленную инъекционную машину.

◇Количество смеси не должно превышать объем, который можно использовать за 30 минут (рекомендуется около 2 кг). Избыточное количество смеси за один раз может вызвать полимеризацию и ускорить затвердевание.

◇Если материал не используется вовремя или его вязкость становится слишком высокой, его следует немедленно вылить и очистить машину толуолом или ацетоном, чтобы избежать засорения машины.

◇Рекомендуется проводить вторую инъекцию через 60-90 минут после завершения первой, чтобы достичь эффективного ремонта.

◇Через 3 дня после инъекции оставшийся эпоксидный материал, затвердевший на облицовке, можно очистить, иглу для инъекций удалить, а отверстие закрыть гидроизоляционным цементом.

Хранение и транспортировка:

◇Хранить в сухом и прохладном месте, подальше от открытого огня и источников тепла. Срок годности в оригинальной упаковке: 12 месяцев.

◇Во время транспортировки строго предотвращать воздействие солнца и дождя, не допускать близости к огню, избегать ударов при ручной погрузке, осторожно предотвращать ослабление захватов и падение.

Copyright © Nantong Yuru Engineering Materials Co., Ltd. All Rights Reserved