टेल:+86 15051225801

ईमेल:[email protected]

टेल:+86 15051225801

ईमेल:[email protected]

Quick Detail:

1. उत्पादों के विभिन्न नाम:

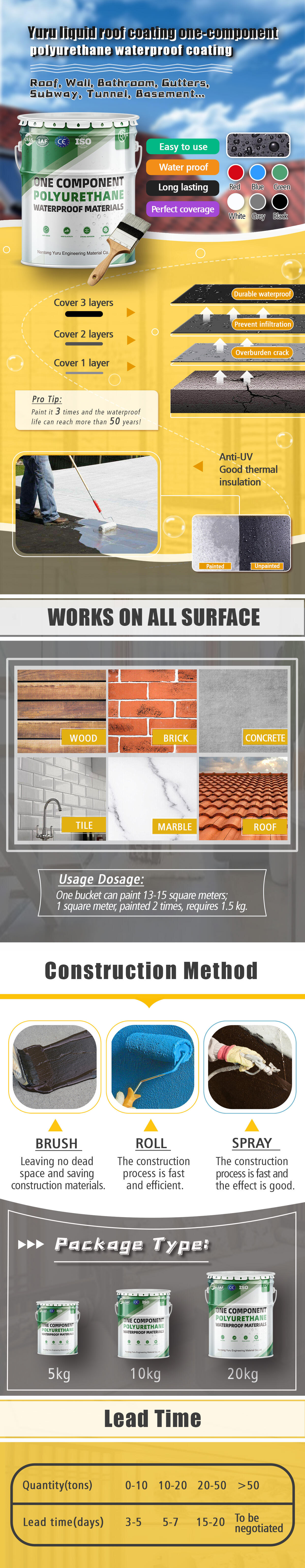

एक-अवयव पॉलीयूरिथेन पानी से रक्षा करने वाला कोटिंग/एक-अवयव पॉलीयूरिथेन पानी से रक्षा करने वाला पेंट/पॉलीयूरिथेन कोटिंग/951 पॉलीयूरिथेन पानी से रक्षा करने वाला कोटिंग

2. मुख्य उपयोग:

यह स्थिर संरचनाओं वाले आंतरिक और बाहरी कंक्रीट इमारतों और सुरंगों और मेट्रो जैसे भूमिगत परियोजनाओं के लिए पानी से रक्षा और पानी से रोकने के लिए उपयुक्त है।

कोई प्रॉब्लम है क्या?

कृपया आपकी सेवा के लिए हमसे संपर्क करें!

| मूल स्थान: | नांतोंग, जियांगसू, चीन |

| ब्रांड नाम: | Yuru |

| मॉडल नंबर: | YR-P101-01 |

| सर्टिफिकेशन: | सीई |

| न्यूनतम ऑर्डर मात्रा: | 100 kilograms |

| मूल्य: | / |

| पैकिंग विवरण: | 20kg/बैरल |

| पैकेजिंग विनिर्देश अनुसूचित हो सकते हैं | |

| डिलीवरी समय: | 7-15 दिन |

| भुगतान शर्तें: | T/T, L/C, paypal, western union |

| सप्लाई क्षमता: | हर महीने 1000 टन |

विवरण:

जल-उपचार एक-अवयव पॉलीयूरिथेन जलरोधी कोटिंग नमी-उपचार और छिपी हुई-उपचार एक-अवयव पॉलीयूरिथेन जलरोधी कोटिंग के आधार पर विकसित की गई एक-अवयव पॉलीयूरिथेन जलरोधी कोटिंग का एक अन्य प्रकार है। यह एक नई पीढ़ी की पर्यावरण-अनुकूल जलरोधी कोटिंग है।

विशेषताएँ:

एक-अंग बैल्कनी बारेल से बाहर तैयार के लिए है, जो निर्माण प्रक्रिया के दौरान दो या अधिक घटकों के अनुपयुक्त मापन के कारण गुणवत्ता अस्थिरता को रोकता है।

एक-अंग बैल्कनी को पानी जोड़कर सीधे ठंडा किया जाता है, जो विषाक्त नहीं है और प्रदूषण मुक्त है।

पानी से बचाने के लिए कोटिंग फिल्म में उच्च खिंचाव शक्ति, उच्च तनाव पर खिंचाव, अच्छी मौसमी प्रतिरोधकता और विकृति के लिए अनुकूलता की शक्ति के गुण होते हैं।

अनुप्रयोग:

छत, भूमिगत पानी से बचाने के परियोजनाएं, आंतरिक रसोइया और बाथरूम पानी से बचाने के लिए;

पार्किंग, पुलों और पुल की छत पानी से बचाने के लिए;

मेट्रो, सुरंगें और भूमिगत परियोजनाओं के पानी से बचाव और रिसाव से बचाव के लिए।

विनिर्देश:

| संख्या: | परियोजना | सूचकांक | |

| प्रकार I | प्रकार II | ||

| 1 | सतह शुष्क होने का समय/घंटा≤ | 12 | |

| 2 | ठोस सूखने का समय/घंटा≤ | 24 | |

| 3 | खिंचाव दृढ़ता/MPa≥ | 2 | 6 |

| 4 | टूटने पर अंतिम खींचाव/%≥ | 500 | 450 |

| 5 | निम्न तापमान पर झुकाव | -35℃, कोई फटलें नहीं | |

| 6 | पानी की अथाहता | 0.3MPa, 120मिन, अथार | |

प्रतिस्पर्धात्मक लाभ:

1. लंबी सेवा जीवन। तीन बार पेंटिंग के बाद, सेवा जीवन 50 साल से अधिक तक पहुंच सकती है।

2. एक-अवयवी पॉलीयूरिथेन वाटरप्रूफ कोचिंग फिल्म में उच्च खिसकाव ताकत, अच्छी विस्तार क्षमता, और उत्तम ऊंचे और निम्न तापमान प्रतिरोध होता है, जो पर्याप्त है ताकि यह आधार परत के कारण तापमान या तनाव से घटने और विस्तार को सहन कर सके।

3. मजबूत चिपकाव। यह विभिन्न आधार परतों से बहुत अच्छी तरह से चिपकता है जो मान्यता प्राप्त हैं और आधार उपचार एजेंट की आवश्यकता नहीं है। फिल्म बनने के बाद, यह लंबे समय तक पानी की डूबी में सहन कर सकता है।

4. एक-अवयवी पॉलीयूरिथेन वाटरप्रूफ कोचिंग फिल्म में अच्छी पानी प्रतिरोध, धातु प्रतिरोध और बैक्टीरिया प्रतिरोध क्षमता होती है, यह प्रदूषणमुक्त है और पर्यावरण सहज है।

5. इसका अनुप्रयोग आसान है। यह एक समय में मोटा अनुप्रयोग किया जा सकता है और कोचिंग फिल्म घनी होती है, पिनहोल या बुलबुलों के बिना।

6. रंग आमतौर पर समायोजनीय होता है, और यह सतह पर विभिन्न रंगों की मानविक मांगों को पूरी करने में भी सक्षम होता है।

01 निर्माण बिंदु :

आधार परत की मांगें: आधार परत को सुलझी हुई, बिल्ली के बिना, अपशिष्ट के बिना, असमान क्षेत्रों के बिना होना चाहिए, और आधार परत में विकृति जोड़े और फissures को सीमेंट मर्टर के साथ समतल किया जाना चाहिए। आधार परत से जुड़े पाइप फिटिंग, स्वच्छता सुविधाओं और फर्श ड्रेन को मजबूती से जोड़ा जाना चाहिए और जोड़े को गाठ किया जाना चाहिए। अंत चिकना होना चाहिए और कोई ढीलापन नहीं होना चाहिए।

कोटिंग का निर्माण: सामान्यतः, कोटिंग की तीन परतें आवश्यक होती हैं। पहली कोटिंग को 12-24 घंटे के लिए समय देने के बाद, दूसरी कोटिंग लगाई जाती है। खुरची की दिशा पहली कोटिंग की दिशा के लम्बवत होती है। यदि आवश्यक हो, डबल्यूट रक्षणात्मक परत का उपयोग करें, ताकि पानी से बचाने वाली परत और डबल्यूट रक्षणात्मक परत के बीच बंधन बल में वृद्धि हो, कोटिंग फिल्म पूरी तरह से सेट होने से पहले इसकी सतह पर चारा रेत खिसकाई जा सकती है। कोटिंग फिल्म जब सैंड पार्टिकल्स के साथ ठोस हो जाती है, तब रक्षणात्मक परत का निर्माण करें।

विवरण प्रसंस्करण: पहले यिन और यांग कोनर्स और पाइप के मूल पर एक पेंट की परत लगाएं, फिर बढ़ावट परत (फाइबरग्लास कपड़ा या गैर-टिस्यू कपड़ा आदि) रखें, और पेंट को बढ़ावट परत को पूरी तरह से पारित करने के लिए बनाएं।

02ध्यान देने की बातें:

जब एक बार चालू कर दिया जाता है, तो आधे घंटे के भीतर इसका उपयोग करें। जब उत्पाद को लंबे समय तक स्टोर किया जाता है, तो पेंट की सतह पर एक पतला फिल्म बन सकती है, जिसे उपयोग के दौरान हटाया जा सकता है और यह उपयोग के प्रभाव पर कोई प्रभाव नहीं डालता।

पेंट का ठोस होने से पहले पानी के अंदर चलने पर प्रतिबंध है। भारी वस्तुओं और तीखी वस्तुओं से पानी के अंदर चलने पर प्रतिबंध है। निर्माण स्थल को वेंटिलेशन दी जानी चाहिए, और निर्माण कर्मचारियों को सुरक्षा के टोपी, ग्लोव्स, काम के जूते और अन्य सुरक्षा सामग्री उपलब्ध होनी चाहिए ताकि त्वचा और आँखों की चार्जिंग से बचा जा सके। स्थल पर आग के स्रोतों की अनुमति नहीं है।

सीमित उपयोग: बारिश, बर्फ, हवा और मरुस्थल, निम्न तापमान का मौसम।

संरक्षण और परिवहन: शुष्क कमरे में स्टोर करें, आग और गर्मी के स्रोतों से दूर। स्टोरिंग के दौरान, इसे उलटे के साथ रखना चाहिए, बाल्टी का मुँह नीचे रहे। परिवहन के दौरान संघर्ष और सूरज और बारिश से बचाएं।

संदर्भ प्रयोग: प्रत्येक मिलीमीटर कोटिंग फिल्म मोटाई के लिए, पेंट का उपयोग होने वाला मात्रानुपात लगभग है: 2.2kg/㎡-2.5kg/㎡।

Copyright © Nantong Yuru Engineering Materials Co., Ltd. All Rights Reserved