Tel: +86 15051225801

Email: [email protected]

Tel: +86 15051225801

Email: [email protected]

Quick Detail:

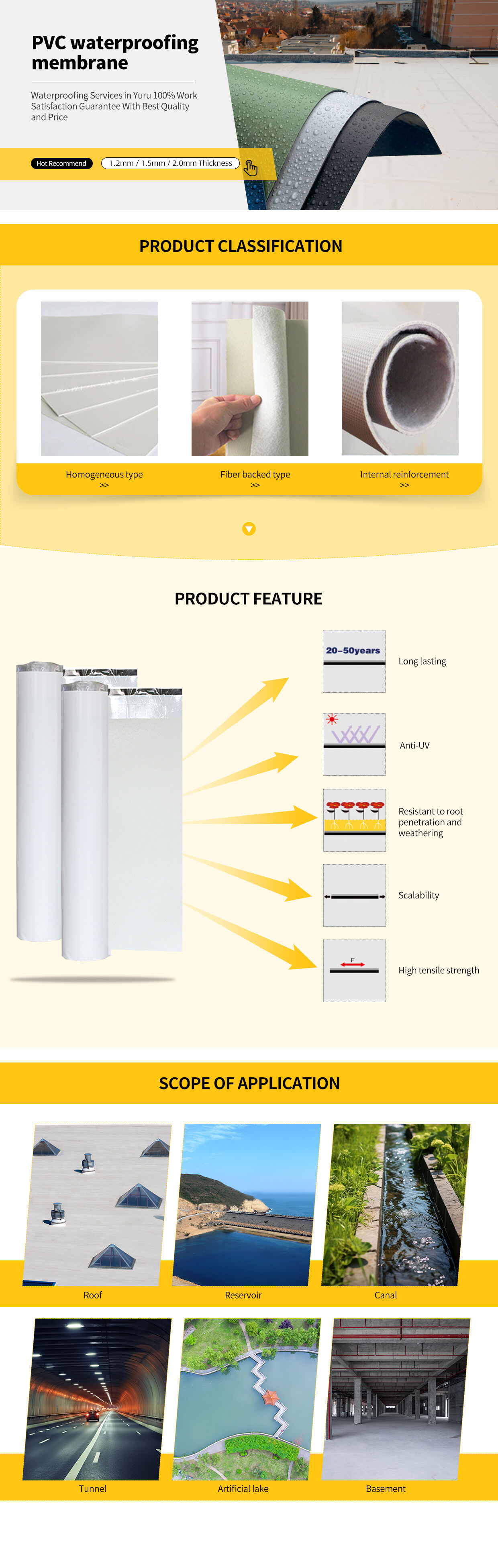

1. Different names of products:

PVC Membrane

pvc sheet waterproof membrane

pvc roofing waterproof membrane

pvc roofing membrane

2. Main uses:

Waterproof and moisture-proof projects such as roofs and basements of various industrial and civil buildings, subway railways, tunnels, water conservancy projects, traffic projects, and grain depots, swimming pools, pools, etc.

| Place of Origin: | Nantong, Jiangsu, China |

| Brand Name: | Yuru |

| Model Number: | YR-PVC |

| Certification: | CE |

| Minimum Order Quantity: | 100 Square Meter |

| Price: | / |

| Packaging Details: | Roll |

| customizable | |

| Delivery Time: | 7-15days |

| Payment Terms: | T/T, L/C,paypal, western union |

| Supply Ability: | 30,000 rolls per month |

Description:

Polyvinyl chloride (PVC) waterproofing membrane is a high-quality, polymer waterproof sheet. The PVC resin is added with plasticizers, anti-UV agents, anti-aging agents, stabilizers and other processing aids, and is produced by extrusion. Polymer waterproof membrane. Due to the unique product formula, this product has a product life that far exceeds that of ordinary waterproof materials. The entire waterproof system has a long life, more than 30 years on the roof and more than 50 years underground. It has been widely used in construction and civil engineering.

Internally reinforced sandwich polyvinyl chloride (PVC) waterproof membrane is a thermoplastic PVC membrane, which is a polymer membrane formed by combining polyester fiber fabric or glass fiber reinforcement. The advanced formula of polyvinyl chloride plastic layer combined with the mesh-structured polyester fiber fabric gives the roll excellent dimensional stability and low thermal expansion coefficient. The inner reinforcing ribs of glass fiber are fully kneaded with the coiled material, so there will be no phenomena such as separation between layers and water immersion. It improves the long-term performance of the membrane when it is directly exposed to the natural environment. At the same time, the unique coating on the surface of the membrane makes the membrane self-cleaning, preventing dust and pollutants in the air from coloring the membrane.

Features:

※Long service life and aging resistance, the roofing material can be used for more than 30 years, and the underground material can be used for 50 years. It has high tensile strength, high elongation and small dimensional change during thermal treatment. It has good low-temperature flexibility and adapts well to changes in environmental temperature differences.

※It has good resistance to root penetration and can be made into planted roofs. It has good resistance to perforation and impact. It is easy to construct, can be welded, strong and reliable, and is environmentally friendly and pollution-free.

※Strong chemical corrosion resistance, suitable for special occasions. The coiled material has good plasticity, and it is convenient and quick to process the details of the edges and corners. Easy maintenance and low cost.

Applications:

Products are widely used in waterproofing, anti-seepage and anti-pollution projects in various fields such as industrial and civil buildings, highways, railways, caves, tunnels, water conservancy, metallurgy, chemical industry, environmental protection, landfills and other fields.

Specifications:

| No. | Project | Index | |||||

| H | L | P | G | GL | |||

| 1 | Thickness of resin layer above middle tire base/mm ≥ | -- | 0.40 | ||||

| 2 | Tensile properties | Maximum pulling force/(N/cm)≥ | -- | 120 | 250 | -- | 120 |

| Tensile strength/MPa≥ | 10.0 | -- | -- | 10.0 | -- | ||

| Elongation at maximum tensile force/%≥ | -- | -- | 15 | -- | -- | ||

| Elongation at break/%≥ | 200 | 150 | -- | 200 | 100 | ||

| 3 | Heat treatment dimensional change rate/%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

| 4 | Low temperature bendability | -25°C No cracks | |||||

| 5 | Impermeable | 0.3MPa, watertight for 2 hours | |||||

| 6 | Anti-hit performance | 0.5kg·m, no water seepage | |||||

| 7 | Resistance to static loadsª | -- | -- | 20kg watertight | |||

| 8 | Seam peel strength/(N/mm)≥ | 4.0 or membrane damage | 3.0 | ||||

| 9 | Right angle tear strength/(N/mm)≥ | 50 | -- | -- | 50 | -- | |

| 10 | Trapezoidal tear strength/N≥ | -- | 150 | 250 | -- | 220 | |

| 11 | Water absorption rate (70℃,168h)/% | After immersion≤ | 4.0 | ||||

| After drying≥ | -0.40 | ||||||

| Note: a. Static load resistance is only required for membranes used for pressed roofing. | |||||||

Competitive Advantage:

1. PVC waterproof membrane has high tensile strength, good elongation and small thermal dimensional change rate.

2. It has good weldability, and the seams become integrated with the base material after hot air welding.

3. It has good water vapor diffusivity, condensation is easily discharged, and moisture and moisture left in the base layer are easily discharged.

4. Resistant to aging, ultraviolet radiation, chemical corrosion, and root penetration.

5. It has good flexibility under low temperature (-20℃).

6. Long service life (30 years on the roof and more than 50 years underground) and no environmental pollution.

7. The colored surface reflects ultraviolet radiation, and the surface of PVC waterproof membrane absorbs less heat and has a low temperature.

8. Excellent flexibility and stretchability, high tensile strength, excellent dimensional stability, high mechanical strength, erosion resistance, root penetration resistance, weather resistance, UV resistance, and hail resistance.

01 Construction points:

According to the characteristics of different projects, mechanical fixing method, gasket fixing method, empty laying method and full adhesive method are generally used for construction. The seams are welded using an automatic hot air welder.

[Mechanical fixing method] is used in roofing projects (especially suitable for waterproofing of metal roofs). Calculate the spacing and quantity of fixing parts according to the project conditions to meet the requirements of wind resistance and buoyancy force. It is fixed with special metal gaskets and self-tapping screws, suitable for different base layers. Construction is fast, safe and reliable.

[Gasket fixation method] Used for side walls of underground projects, side walls and vaults of tunnels. It is not affected by the flatness and temperature of the base layer. Special PVC gaskets are used to make the roll material adapt to the deformation of the base layer and have strong construction capabilities. convenient.

[Blank paving method] It is used for basement floors, roofs, building floors, roofs, and pedestrian roofs. It does not require gluing and fixing. After laying, the coils are welded and spliced directly with a hot air welder. If necessary, on the waterproof layer Add a layer of geotextile as a protective layer. The construction is simple and fast and is not affected by the environment, reducing construction costs.

[Full bonding method] Used for basement side walls and exposed roofs. L-type polyvinyl chloride (PVC) rolls are selected, and a special matching adhesive is used to firmly bond the non-woven fabric on the surface of the roll to the base layer. The non-woven fabric under the roll plays a role in isolation, protection and buffering.

02Matters need attention:

·During storage and transportation, products of different types and specifications should be stored separately and should not be mixed; avoid sunlight and rain, and pay attention to ventilation;

Copyright © Nantong Yuru Engineering Materials Co., Ltd. All Rights Reserved